-

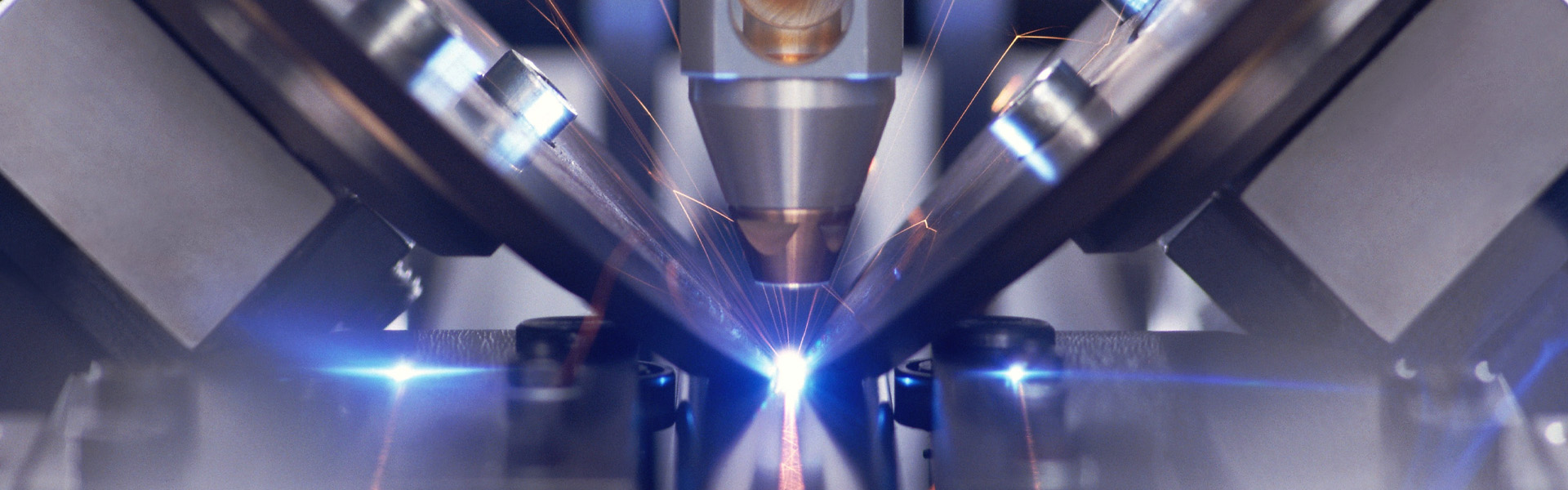

Laser Marking Solution

In the electronics industry, ultraviolet laser uses cold processing technology to engrave QR codes on PCB boards and chips, with a minimum line width of 0.01mm, to avoid thermal damage. In the medical field, the UDI mark created by picosecond laser has not fallen off after 72 hours of salt spray testing, meeting FDA traceability standards and ensuring the safety of surgical instruments. In the automotive manufacturing industry, it is suitable for marking the QR code on the shell of new energy batteries, and can also engrave brand logos on the leather interior, completing personalized pattern switching in 30 seconds. In the aerospace field, laser marking on high-temperature resistant materials such as titanium alloys and tungsten steel meets the AS478-3 standard and is still clear and readable even in extreme environments. From micro chips to giant components, laser marking machines are reshaping industrial marking accuracy and efficiency.