-

Soldering Solution

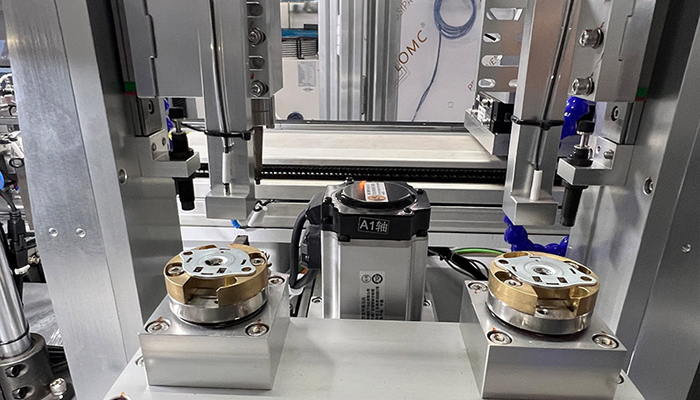

The field of electronic manufacturing is the main battlefield for soldering. Resistors, capacitors, and other components on PCB boards are often soldered using wave soldering or reflow soldering, with solder joint accuracy of ± 0.1mm, in compliance with IPC-A-610 electronic assembly standards, ensuring stable circuit conductivity and supporting the miniaturization development of devices such as mobile phones and computers. In the electronics of new energy vehicles, laser assisted soldering of on-board chip pins can avoid high temperature damage to the chip. The temperature resistance range of solder joints is -40-85 ℃, meeting the reliability requirements of AEC-Q100. In the medical field, micro circuit boards for blood glucose meters and electrocardiogram monitors rely on manual or semi-automatic soldering, with solder joint diameters of only 0.2mm, balancing conductivity and lightweight structure. In the scenario of home appliance maintenance, soldering is a key process that supports the precision and low-cost manufacturing of electronic devices due to its ease of operation, rapid repair of air conditioning motherboards and refrigerator temperature controller interfaces, and reduced equipment maintenance costs.

-

Metal Welding Solution

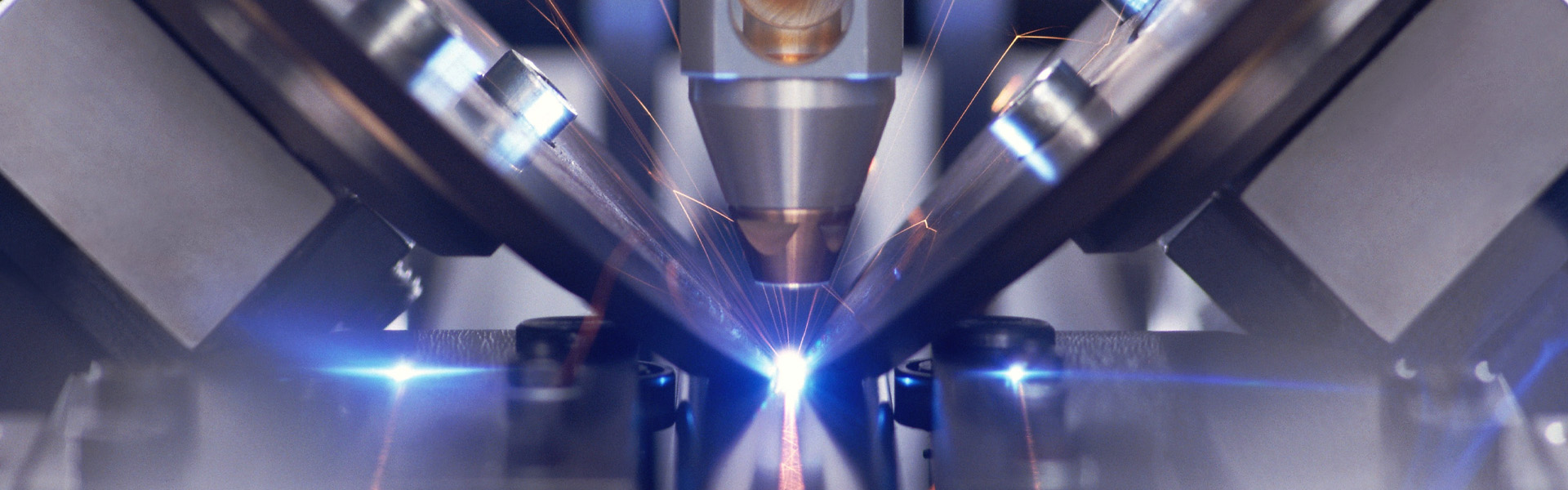

Metal welding achieves high-strength and airtight connections of metals such as steel, aluminum, and titanium alloys through high-temperature fusion or pressure. It is a cornerstone process in aerospace, automotive, energy, and other fields, suitable for manufacturing needs from micro components to giant equipment. In the aerospace field, the titanium alloy fuselage frame is welded using laser deep penetration welding, with the heat affected zone controlled within 0.1mm, and the weld strength reaching over 90% of the base material, in compliance with AMS 2680 standard, ensuring safety in extreme flight environments. In the manufacturing of new energy vehicles, laser brazing technology for battery trays can achieve 0.02mm precision welding, and the salt spray resistance test of the weld seam exceeds 1000 hours, greatly improving the anti-corrosion performance of the battery pack. In the petrochemical industry, long-distance oil and gas pipelines rely on submerged arc welding, with a single weld thickness of 20mm and a pressure resistance rating in accordance with API 1104 standards, meeting the requirements of high-pressure transportation. In the medical field, titanium alloy artificial joints use laser micro welding, with a welding point diameter of only 0.3mm and an accuracy of ± 2 μ m. It balances biocompatibility and structural stability, promoting the upgrading of metal manufacturing towards precision and high reliability.

-

Plastic welding solution

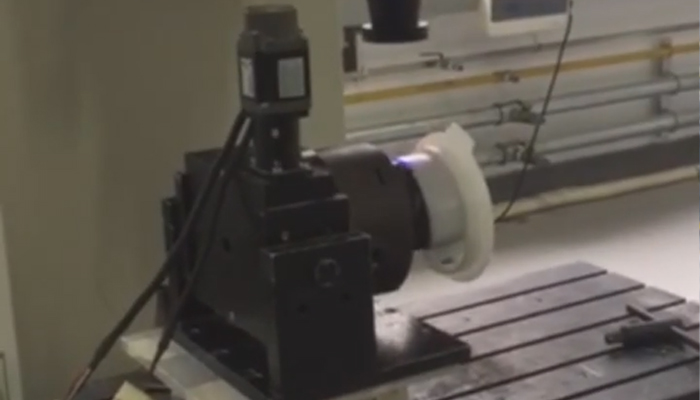

In the automotive field, ultrasonic twist welding reduces the bumper wall thickness to below 2.5mm, while laser welding achieves an IP69K sealing level for millimeter wave radar housings, ensuring stable operation in environments ranging from -40 ℃ to 120 ℃. In the medical industry, 2 μ m laser welding achieves molecular bonding of transparent components, reducing the defect rate of insulin pumps by 40%. Ultrasonic welding meets FDA 21 CFR Part 11 standards, ensuring sterility and traceability. In the field of electronics, laser welding accuracy reaches ± 5 μ m, 976nm wavelength technology ensures high-strength connection of sensor housing, and the heat affected zone is controlled at the micrometer level. The packaging industry uses 35kHz ultrasonic technology to complete the sealing of cylindrical bags and punching of handheld holes in one step, with high weld strength and improved material utilization. From automotive lightweighting to medical sterile requirements, plastic welding drives manufacturing towards efficient and environmentally friendly upgrades.