-

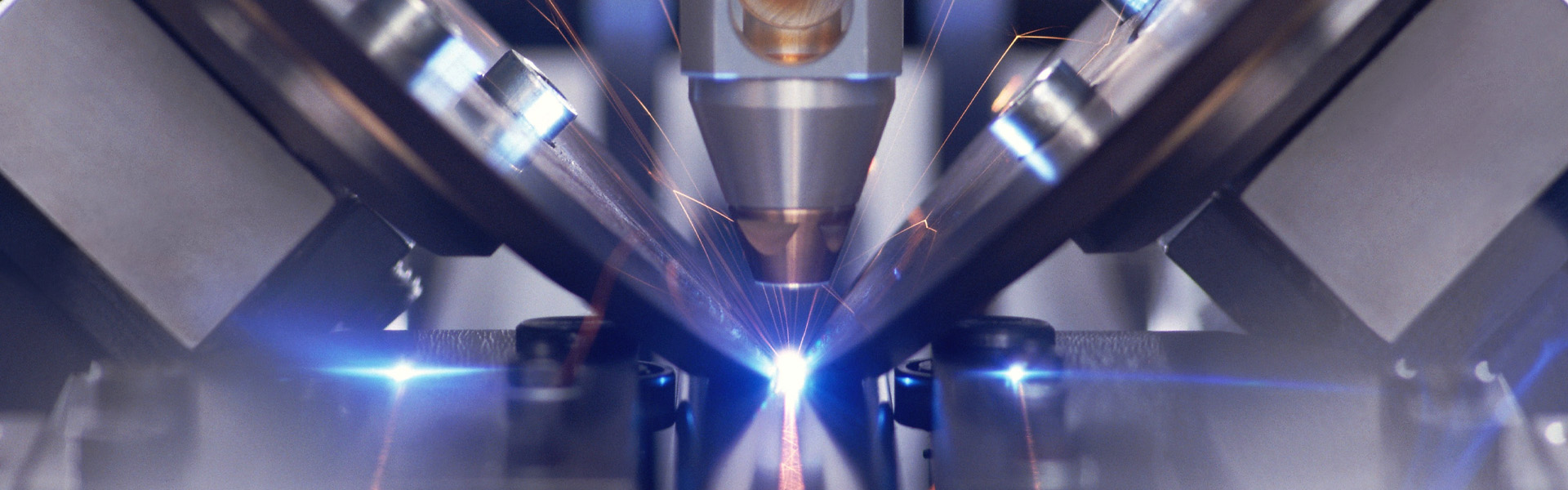

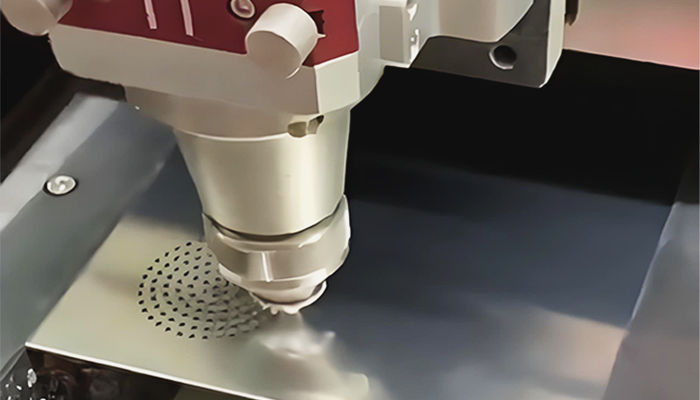

Laser cutting solution

In the field of metal processing, fiber laser cutting machines can efficiently cut carbon steel, stainless steel, and titanium alloys. In the aerospace industry, this enables the cutting of titanium alloy components with a narrow gap of 0.1mm. Coupled with inert gas protection, the heat affected zone is controlled within 50 μ m. In automobile manufacturing, 3D five axis laser cutting machines do not require molds, reducing bumper processing costs by 69% and increasing material utilization to over 90%. The CO ₂ laser cutting machine in the electronics industry focuses on cutting non-metallic thin films with an accuracy of 10 μ m, meeting the needs of precision parts such as flexible OLEDs. The medical field utilizes its sterile processing characteristics to achieve zero burr cutting of stainless steel instruments and titanium alloy implants, promoting manufacturing innovation towards efficiency and precision.