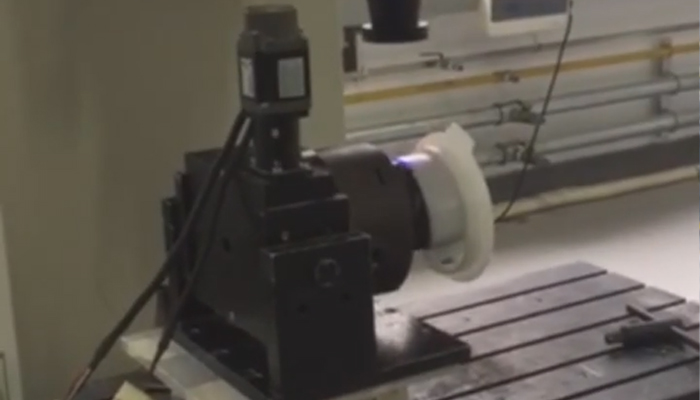

1500W air-cooled handheld welding

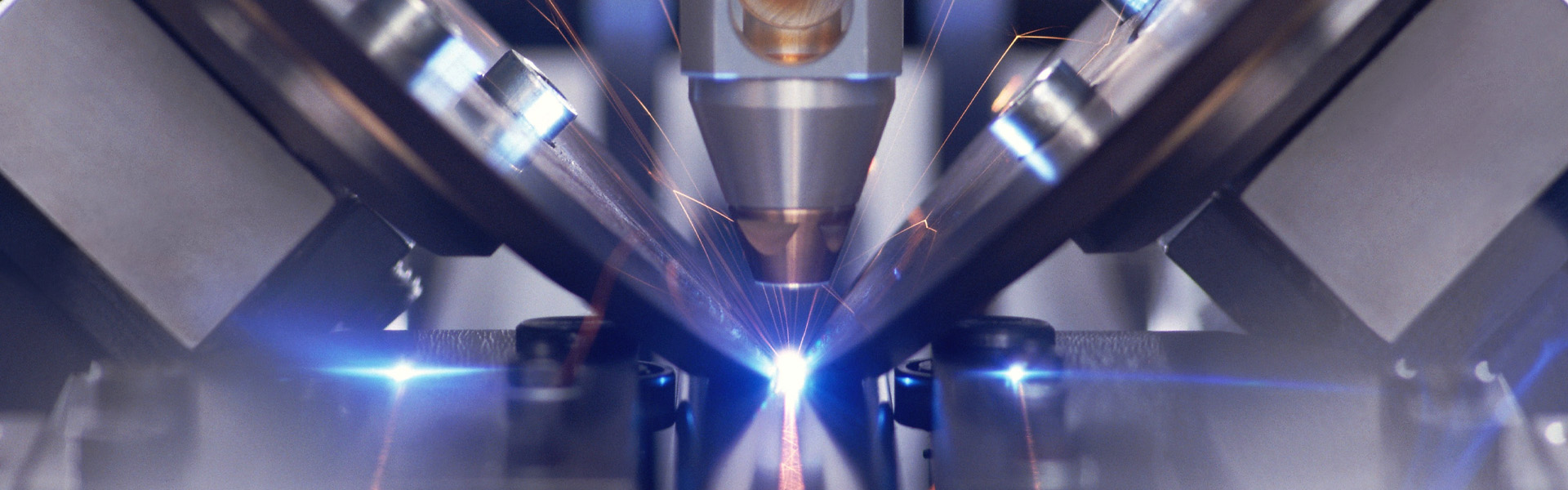

The principle of laser welding machine

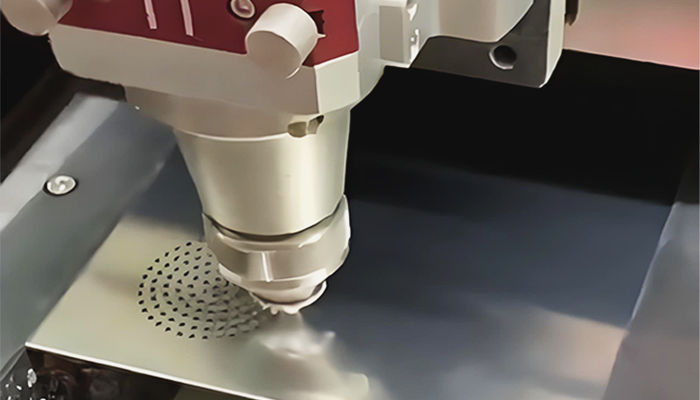

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

The characteristics of laser welding

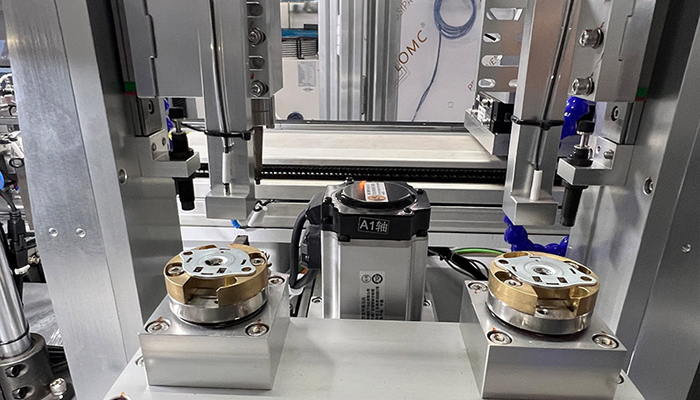

1. It is a new type of welding method, mainly for welding thin-walled materials and precision parts.

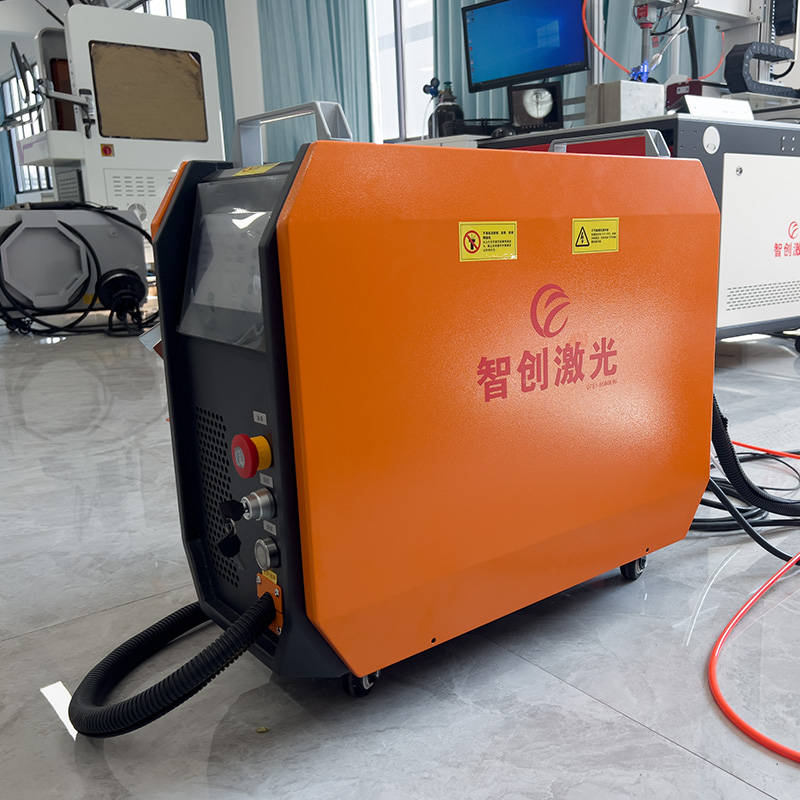

Appearance of welding machine (subject to the actual machine)

2. It can realize spot welding, butt welding, lap welding, sealing welding, etc.

3. High aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, no need for post-welding treatment or only simple treatment

4. High weld quality, can be precisely controlled, high positioning accuracy, easy to realize automation.

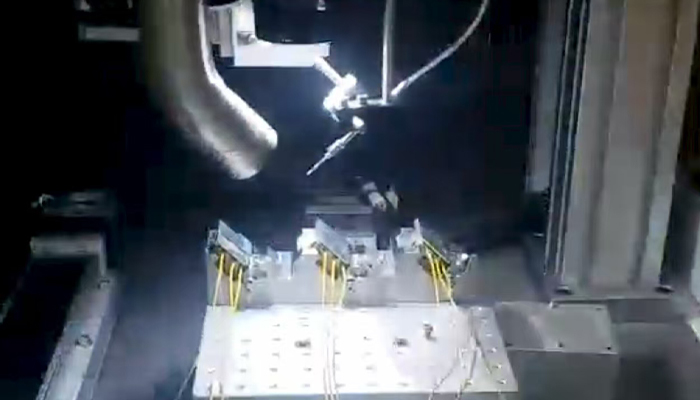

Application field

Contace us