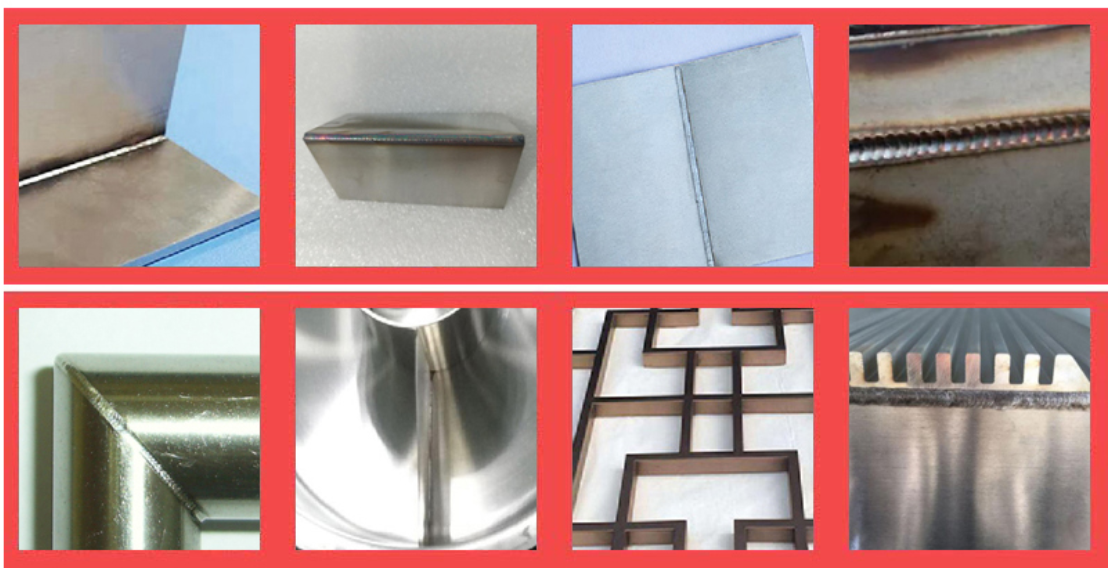

A high-energy-intensity laser beam is directly irradiated onto the material surface. Through the interaction between the laser and the material, the interior of the material melts, and then cools and crystallizes to form a weld seam. The welding process does not require pressure.

The handheld welding head is equipped with a five-meter imported optical fiber, which is flexible and convenient, and can achieve outdoor welding. The operation mode of the handheld welding torch can achieve welding of any part and any Angle of the workpiece. Intelligent dual-optical path switching ensures uniform energy distribution in time-sharing and light-splitting. Applicable to various complex weld seams and spot welding of various devices; The CCD camera monitoring system facilitates observation and precise positioning.