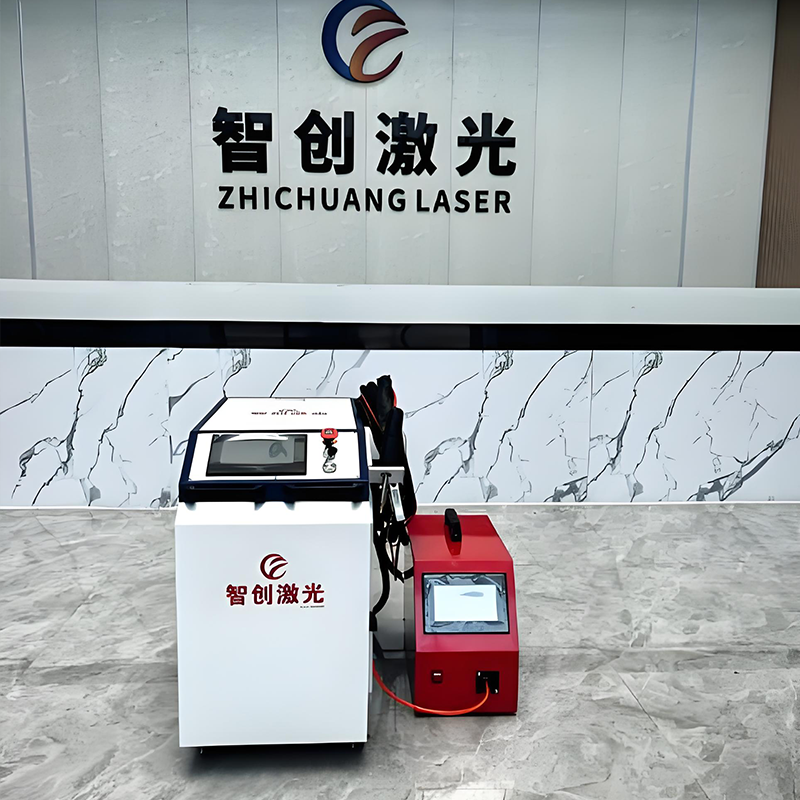

| Configuration and Parameters | ||||||

| Serial Number | Product Name | specifications | unit | quantity | notes | |

| 1 | Cabinet | Smart Creation Customization | cover | 1 | ||

| 2 | laser device | Chuangxin MFSC-1500 | cover | 1 | ||

| 3 | Water cooler | Smart Creation Customization | tower | 1 | ||

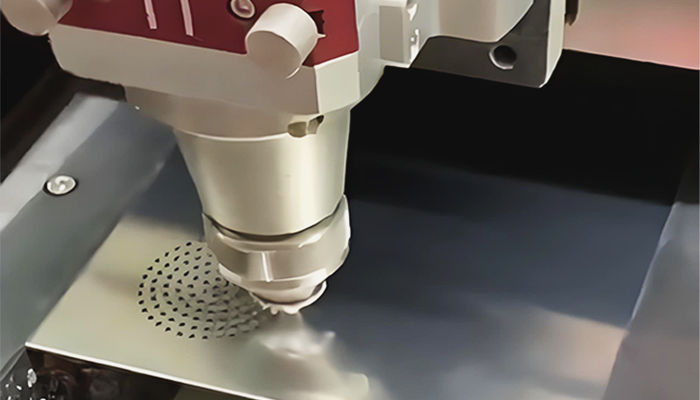

| 4 | Welding head | Smart Creation Customization | tower | 1 | ||

| 5 | control system | Smart Creation Customization | cover | 1 | ||

| 6 | wire feeder | Smart Creation Customization | cover | 1 | ||

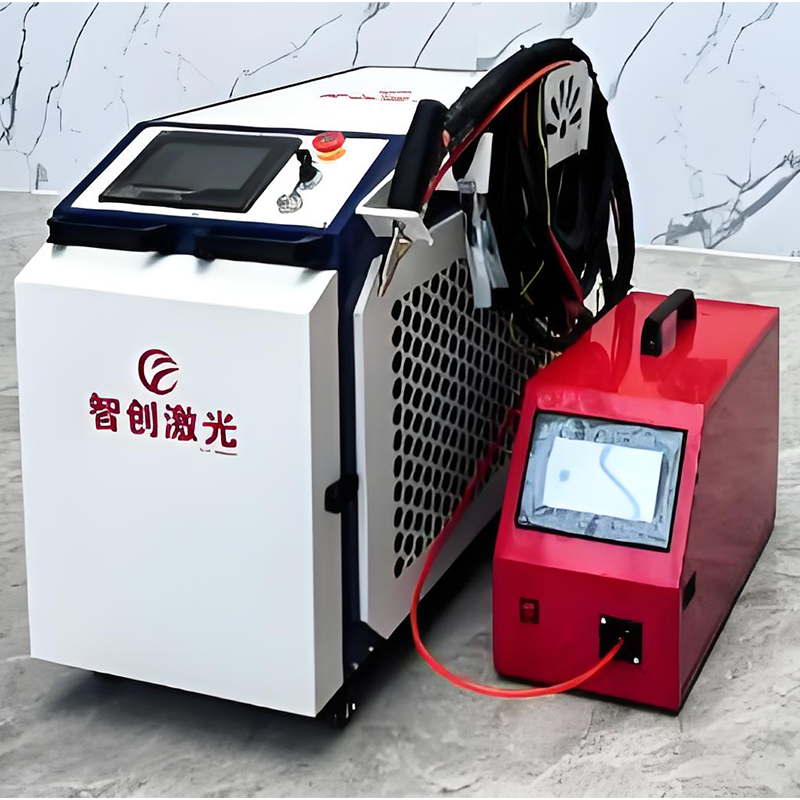

| Serial Number | characteristic | describe | remarks | |||

| 1 | Center wavelength (nm) | 1060—1080 | ||||

| 2 | Laser power (w) | 1500 | ||||

| 3 | Fiber length (m) | 10 | Exposed 8m | |||

| 4 | Gun head weight (kg) | 0.7 | ||||

| 5 | Cooling method | water-cooling | ||||

| 6 | Operating environment | Ring mirror temperature 10-35 ℃, relative humidity 30% ≤ RH ≤ 85%, no condensation, no condensation Conclusion“ | ||||

| 7 | Electricity requirements | 220V±5% , 50Hz | ||||

| 8 | Overall power (kw) | 7 | ||||

| 9 | The overall dimensions of the machine are approximately (mm), excluding the wire feeder | 950*520*800 | Portable small cabinet | |||

| 10 | Whole machine weight (kg) | 150 | Portable small cabinet | |||

| 11 | security level | Class IV | ||||

| 12 | Total power protection level | IP54 | ||||