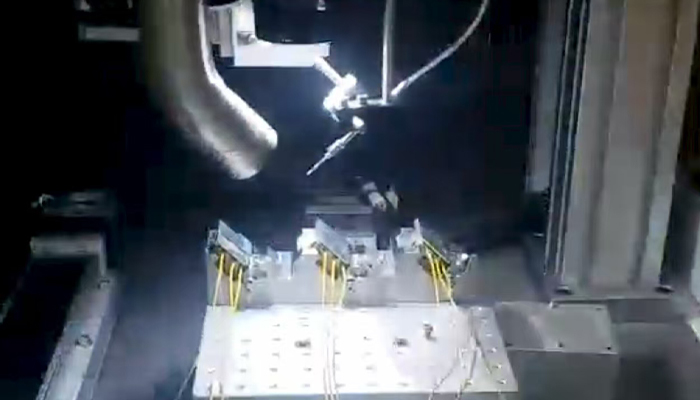

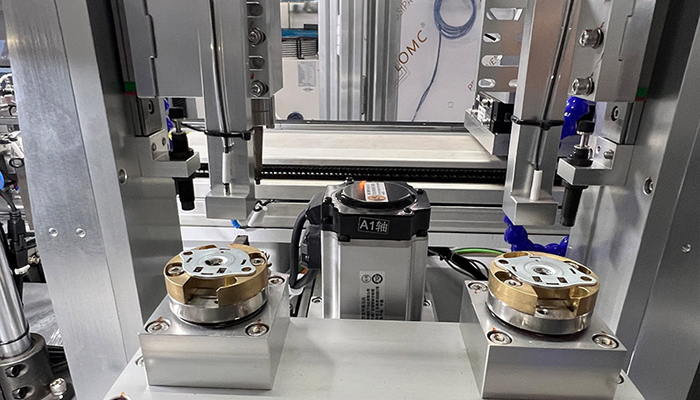

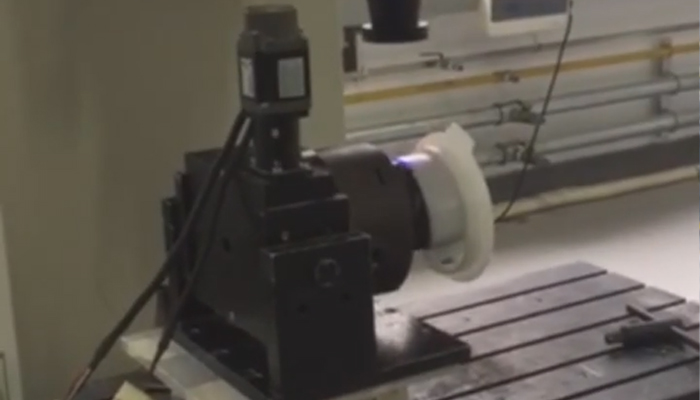

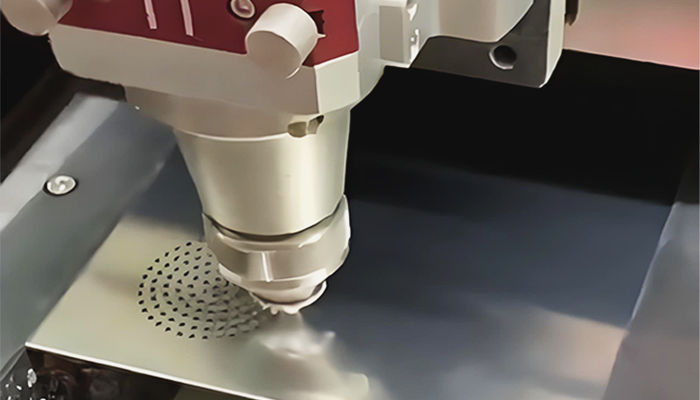

Metal Welding Solution

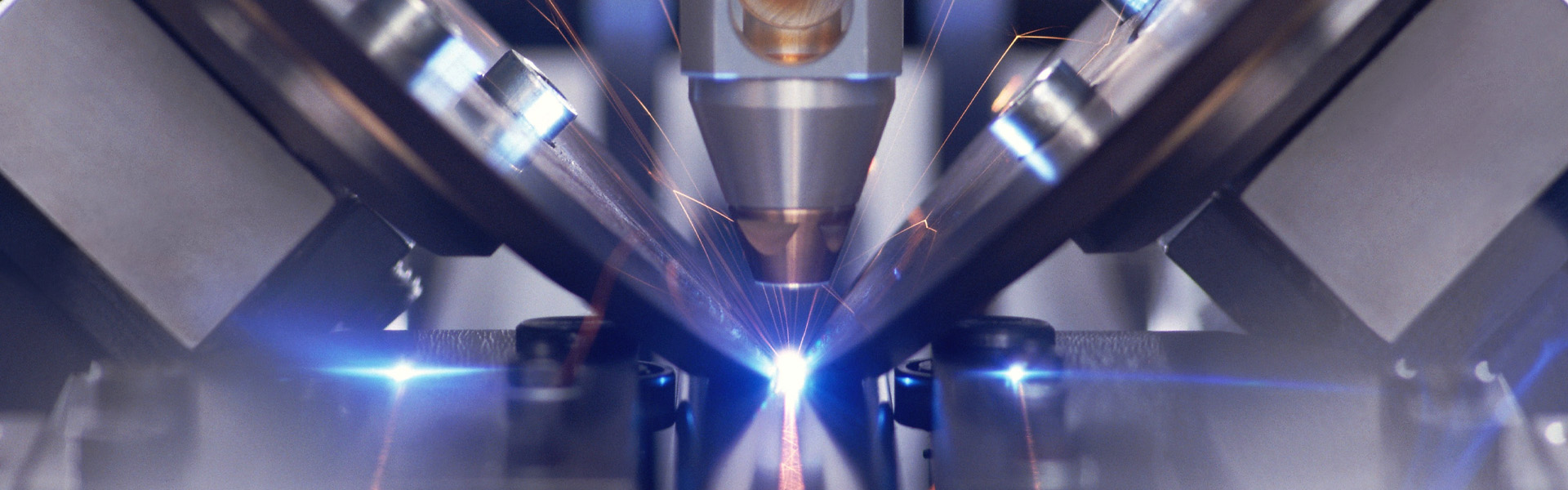

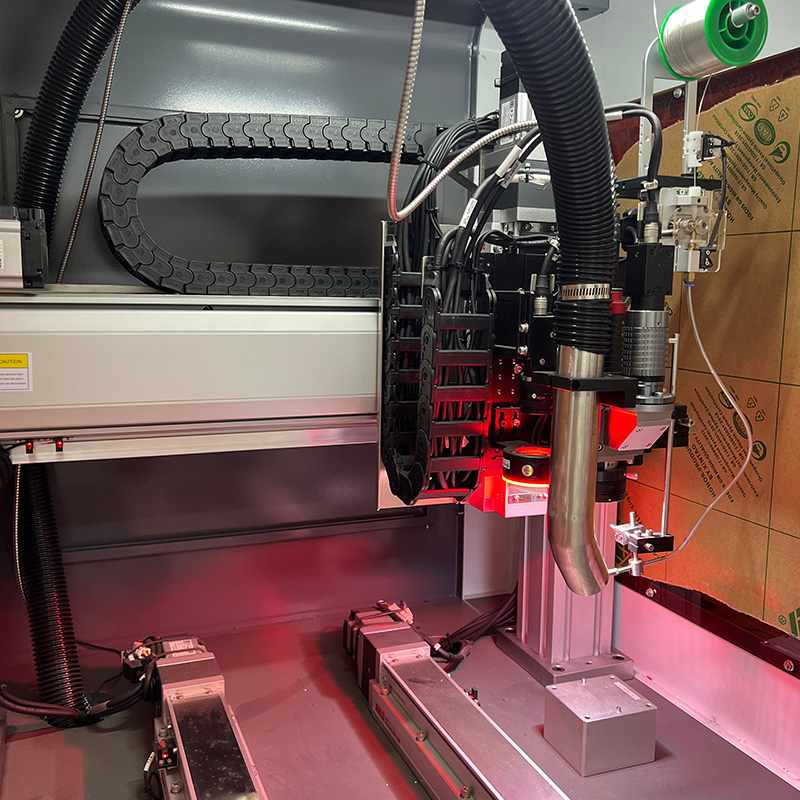

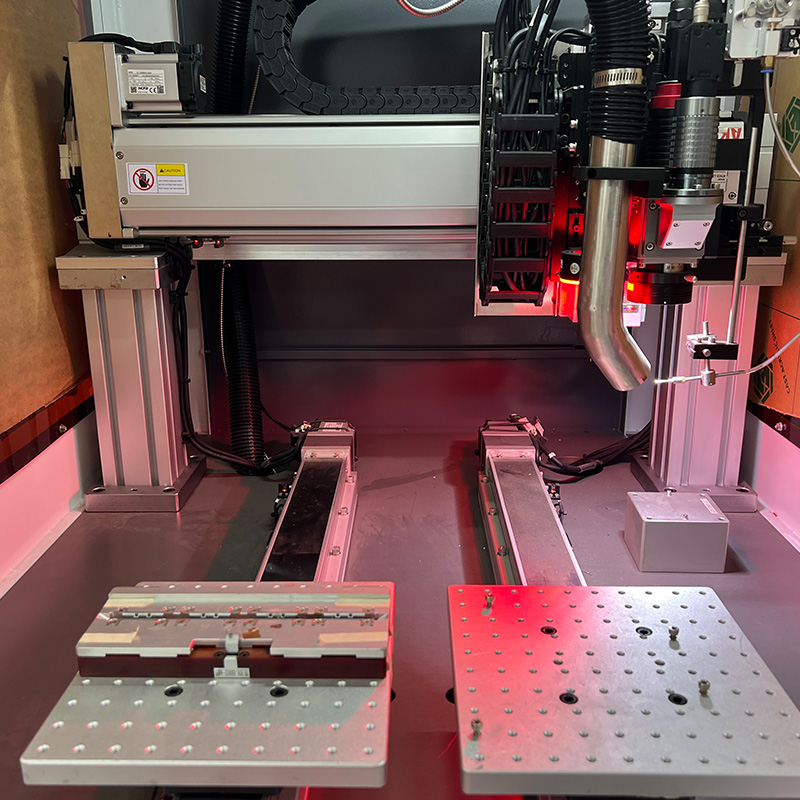

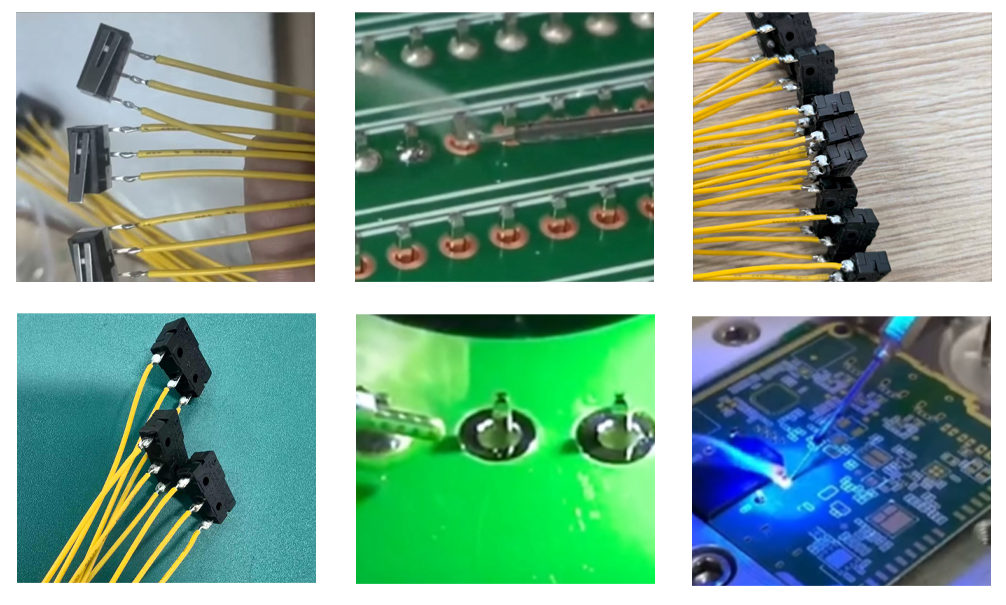

Metal welding achieves high-strength and airtight connections of metals such as steel, aluminum, and titanium alloys through high-temperature fusion or pressure. It is a cornerstone process in aerospace, automotive, energy, and other fields, suitable for manufacturing needs from micro components to giant equipment. In the aerospace field, the titanium alloy fuselage frame is welded using laser deep penetration welding, with the heat affected zone controlled within 0.1mm, and the weld strength reaching over 90% of the base material, in compliance with AMS 2680 standard, ensuring safety in extreme flight environments. In the manufacturing of new energy vehicles, laser brazing technology for battery trays can achieve 0.02mm precision welding, and the salt spray resistance test of the weld seam exceeds 1000 hours, greatly improving the anti-corrosion performance of the battery pack. In the petrochemical industry, long-distance oil and gas pipelines rely on submerged arc welding, with a single weld thickness of 20mm and a pressure resistance rating in accordance with API 1104 standards, meeting the requirements of high-pressure transportation. In the medical field, titanium alloy artificial joints use laser micro welding, with a welding point diameter of only 0.3mm and an accuracy of ± 2 μ m. It balances biocompatibility and structural stability, promoting the upgrading of metal manufacturing towards precision and high reliability.

Read details