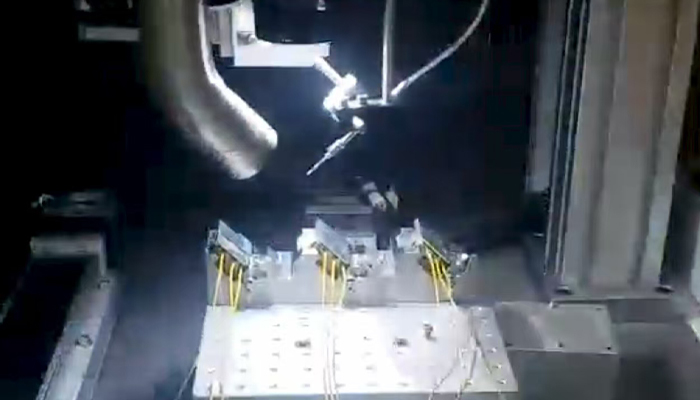

Fiber optic continuous laser automatic welding machine(Laser hardware welding)

The principle of laser welding machine

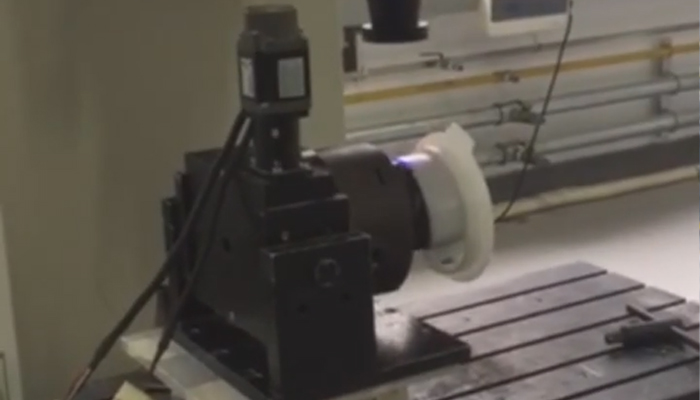

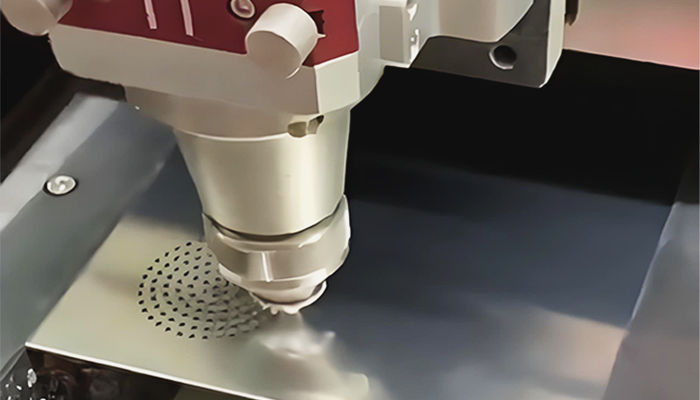

Laser welding is the process of using a high-energy density laser beam as a heat source to focus the laser beam on a very small area through an optical system, creating a highly concentrated heat source zone at the welded area in a very short period of time, thereby melting the welded material and forming a solid weld or seam. The smaller the focused spot, the higher the power density of the spot at the focal point, and the higher the welding efficiency under the same welding penetration requirements. Similarly, under the same welding efficiency requirements, the welding depth after welding is deeper. Laser welding is the use of high-energy laser pulses to locally heat materials in small areas. The energy radiated by the laser diffuses through the interior of the material through thermal conduction, melting the material and forming a specific molten pool.

The characteristics of laser welding

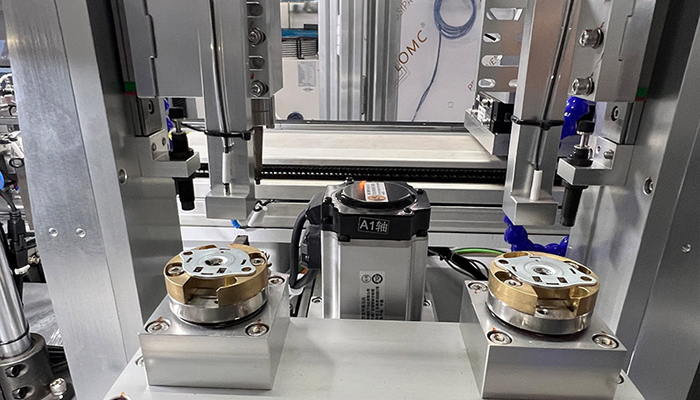

◆The software operation is simple, controlled by industrial PLC or motion control card, and the workstation can perform four-dimensional internal trajectory movement. It can weld any shape composed of points, lines, circles, squares, or lines and arcs.

◆The overall performance is stable, the lifespan is long, and maintenance free is basically achieved.

◆High aspect ratio, small weld width, small impact zone, small deformation, and fast welding speed.

◆The equipment has high reliability and can work continuously and stably for 24 hours, meeting the needs of large-scale processing and production.

◆The workbench is equipped with ball screws and linear guides for easy and flexible movement, three-dimensional movement, and precise positioning.

Application field

Contace us