Product

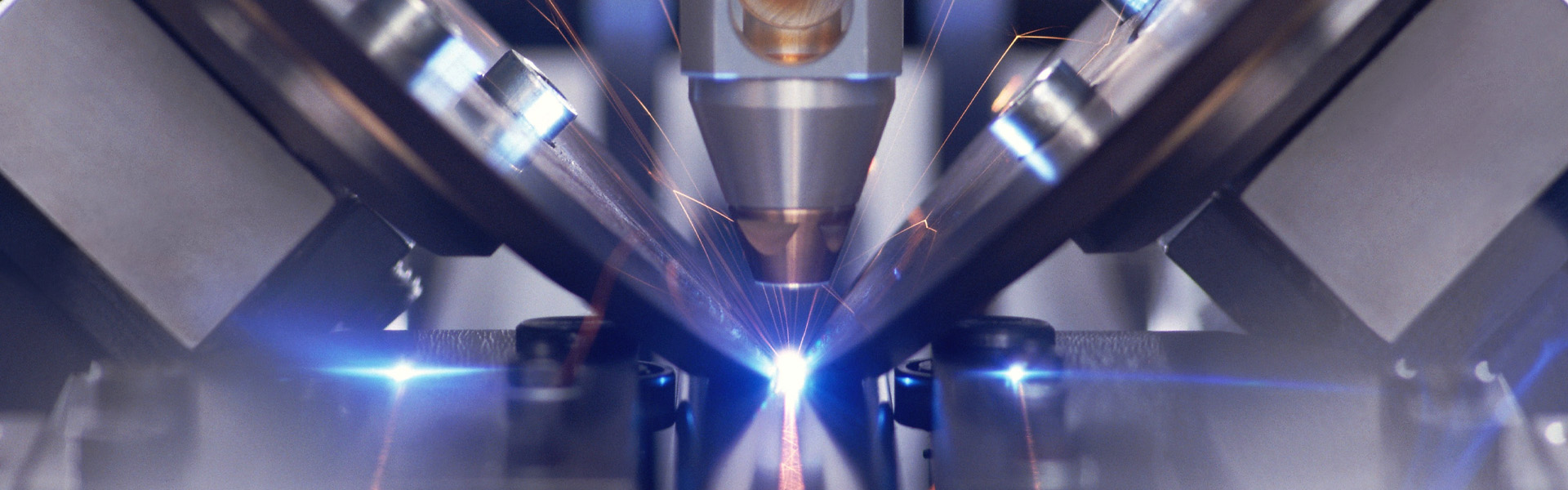

The field of lasers

-

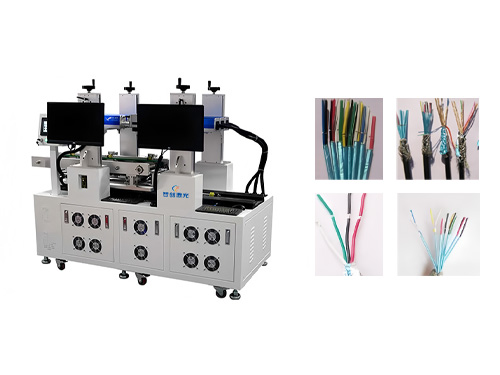

Focused laser wire stripper

The high-speed scanning galvanometer system features stable output power, excellent optical mode and outstanding beam quality

More+ -

LED copper wire laser polishing machineMore+

-

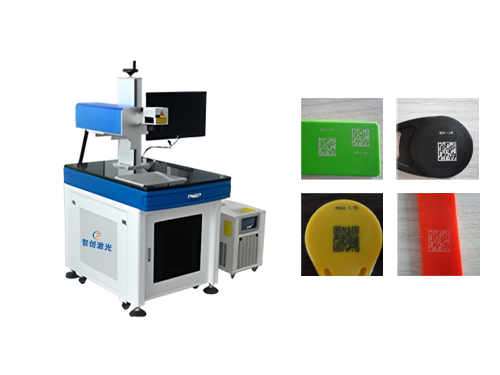

Standard UV ultraviolet laser marking machine

Ultraviolet laser marking machines belong to the series of laser marking machines, but they are developed using 355nm ultraviolet lasers. This machine adopts the third-order intraccavity frequency doubling technology. Compared with infrared lasers, the focused spot of 355nm ultraviolet light is extremely small, which can greatly reduce the mechanical deformation of materials and has a small thermal impact during processing. Therefore, it is mainly used for ultra-fine marking and engraving. It is particularly suitable for application fields such as marking and micro-hole drilling of food and pharmaceutical packaging materials, high-speed division of glass materials, and complex graphic cutting of silicon wafers.

More+ -

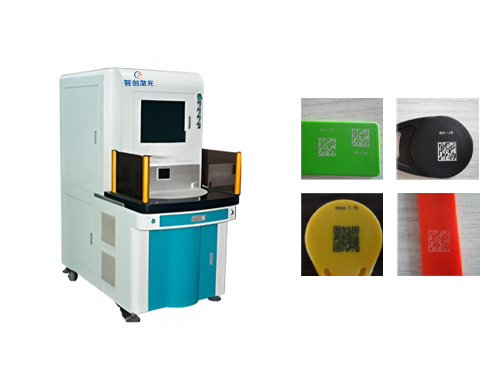

Enclosed UV ultraviolet laser marking machine

Ultraviolet laser marking machines belong to the series of laser marking machines, but they are developed using 355nm ultraviolet lasers. This machine adopts the third-order intraccavity frequency doubling technology. Compared with infrared lasers, the focused spot of 355nm ultraviolet light is extremely small, which can greatly reduce the mechanical deformation of materials and has a small thermal impact during processing. Therefore, it is mainly used for ultra-fine marking and engraving. It is particularly suitable for application fields such as marking and micro-hole drilling of food and pharmaceutical packaging materials, high-speed division of glass materials, and complex graphic cutting of silicon wafers.

More+ -

Water-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+ -

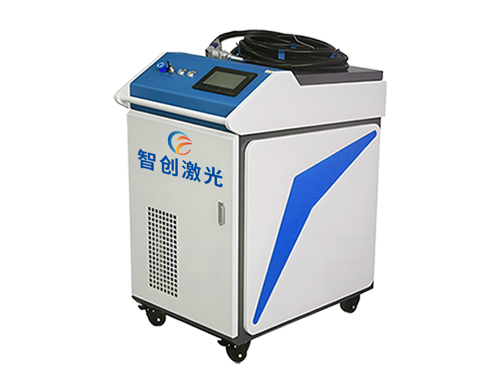

1200W air-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+