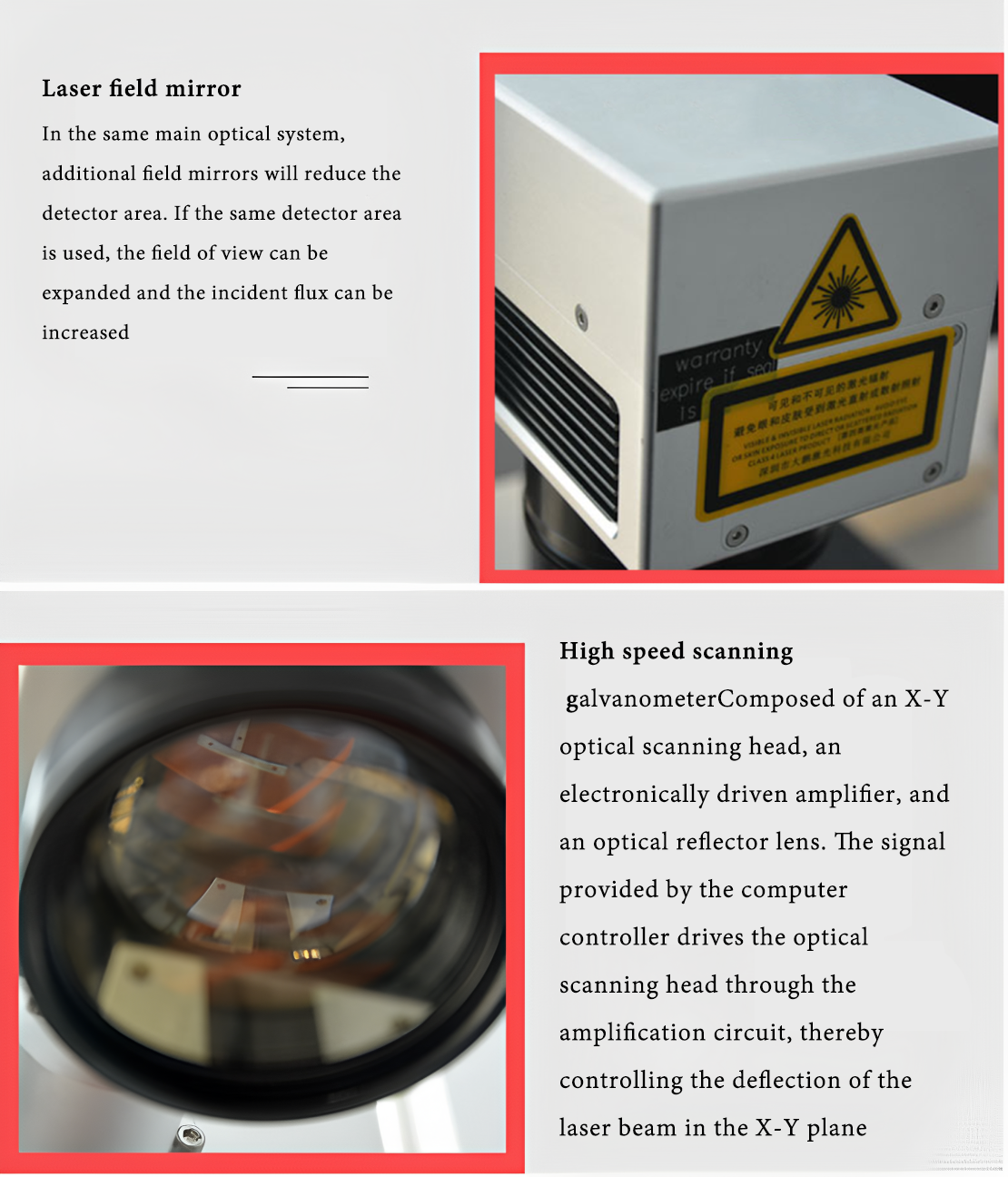

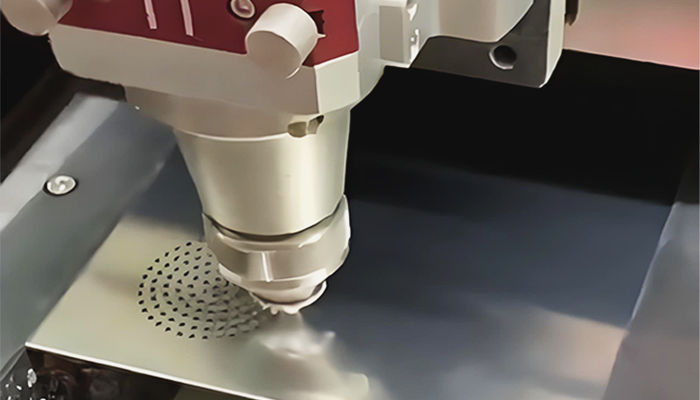

The image of the product to be marked is collected through the built-in camera. The image processing software is used to analyze and process the image, automatically identifying and locating the position, shape, Angle and other information of the product. Then, according to the preset program instructions, the laser is controlled to emit a high-energy-density laser beam to locally irradiate the workpiece, causing the surface material to vaporize or undergo a chemical reaction that changes color. Thus leaving a permanent mark.

Application field

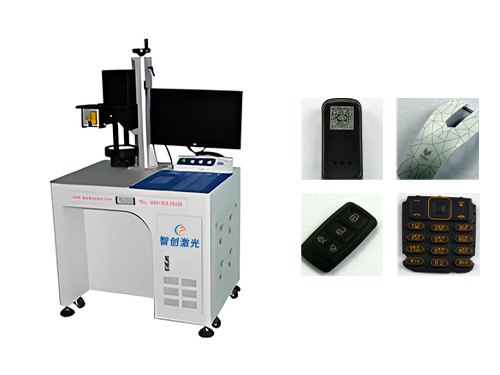

Electronics industry: It is used for marking the casings, chips, circuit boards and other components of electronic products such as mobile phones and computers, marking information such as model numbers, serial numbers and production dates.

Automobile manufacturing: It can mark components such as car engines, gearboxes, and wheels, indicating part numbers, production dates, traceability codes, and other information.

Medical devices: Syringes, scalpels, pacemakers and other medical devices are marked with product models, specifications, batches, expiry dates and other information to facilitate quality traceability and management.Jewelry: Marking, engraving, patterns, brand logos, etc. on gold and silver jewelry, diamonds, jade, etc., to increase the added value and aesthetic appeal of the products.

Development trend