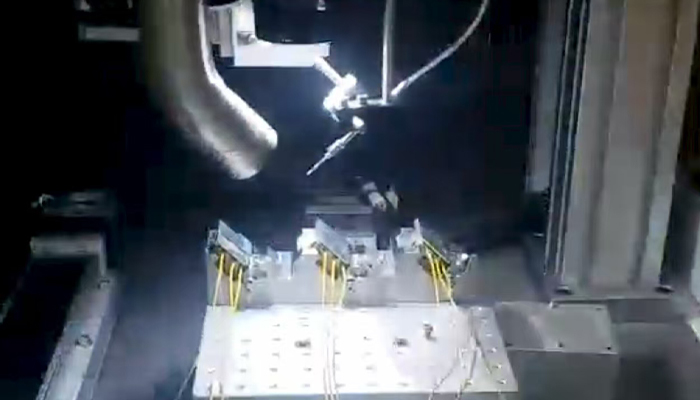

Assembly line visual positioning laser marking machine

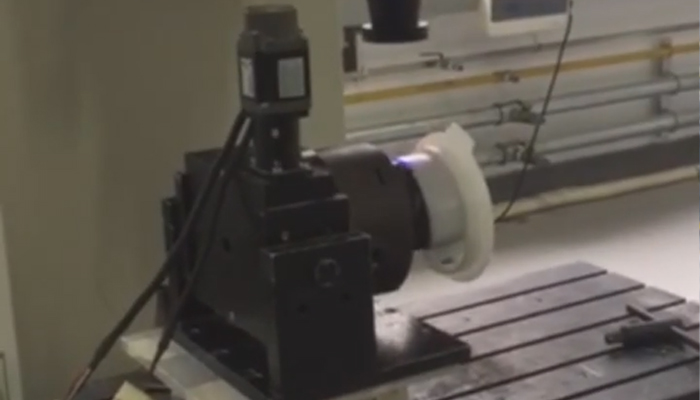

The principle of laser welding machine

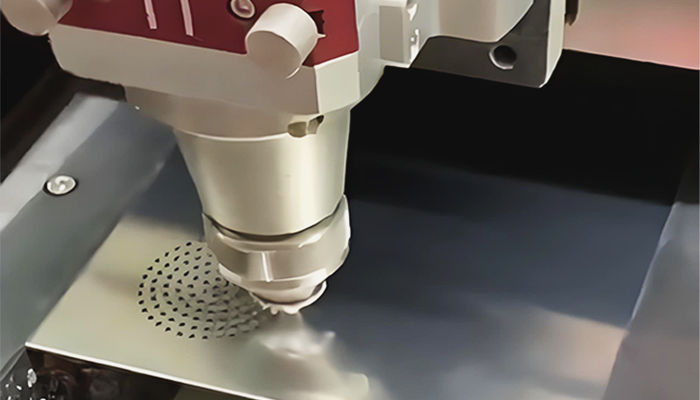

The image information of products on the assembly line is collected in real time through industrial cameras. The images are analyzed and processed by using image processing algorithms to quickly and accurately identify the position, posture, shape and other features of the products, and then this information is transmitted to the control system. The control system precisely controls the movement of the laser and the scanning galvanometer according to the preset marking content and position requirements, enabling the laser beam to accurately illuminate the designated position of the product for marking, thus achieving high-speed and high-precision automated marking.

The characteristics of laser welding

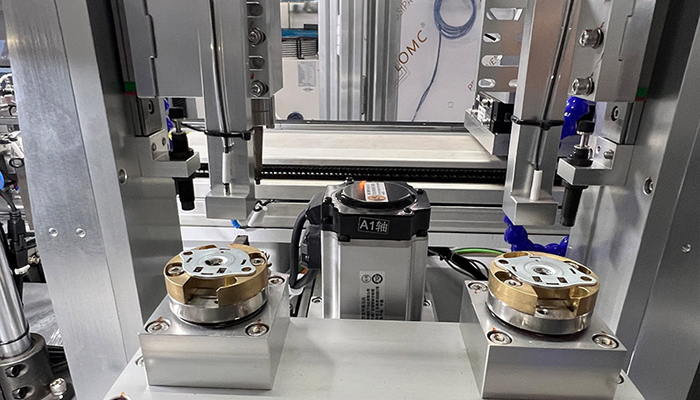

High-precision positioning: It can accurately identify the position and posture of the product, with a position accuracy of ±0.03mm or even higher.

High-efficiency automation: Seamlessly integrated with the assembly line, it can achieve unmanned automatic marking, saving labor costs and improving production efficiency.

Strong flexibility: The products can be placed freely without the need for fixtures for positioning, and can meet the marking requirements of products of different shapes, sizes and materials.

Visual inspection function: Some devices also have a visual inspection function, which can inspect the marking quality after marking, such as character clarity and integrity, to promptly identify defective products.

Application field

Contace us