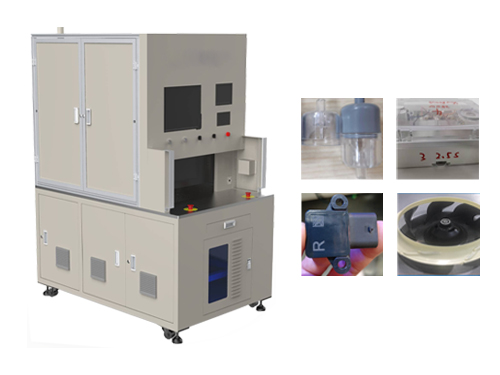

Home appliance industry: various household electronic device product packaging, such as air conditioning fan blades, liquid cooled lamps LED、 Water cup, etc.

Automotive industry: such as automatic door locks, keyless entry and exit devices, start switches, tire pressure monitors, instrument panels, headlights and taillights, intake manifolds, fuel injectors, gear shift frames, engine sensors, cab frames, hydraulic fuel tanks, transmission filters, etc.

Medical field: such as manufacturing liquid storage tanks, liquid filtration equipment, hose connectors, ostomy bags, hearing aids, transplants, hemodialysis, microfluidic devices for analysis, etc

Weldable materials: ★ Fluorine resin (PFA), olefin resin (PE, PP) ★ Engineering resin (PBT, PA6, PC, POM) ★ Super engineering resin (PSF, PPS, PEEK, PEI, LCP) ★ Welding of transparent materials (PC, PVC, PP, PMMA, PET) → Achieving stacking welding with wall thicknesses of 3mm and 5mm ★ Welding of non-woven fabrics (PP materials)