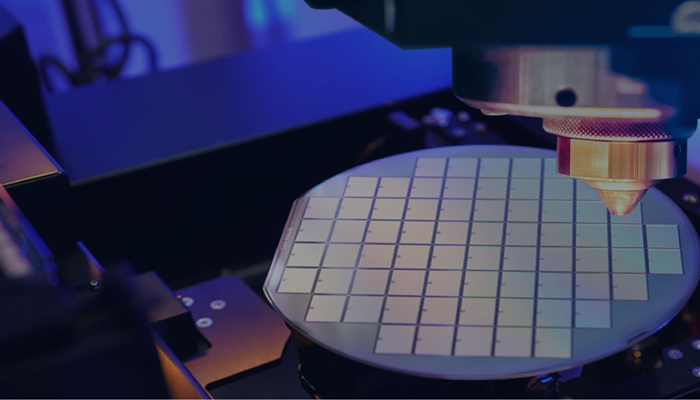

A YAG laser is a type of laser that uses a xenon lamp as the laser source and a YAG laser crystal as the laser working substance. The laser power supply first pre-ignites the pulsed xenon lamp. Through the discharge of the pulsed xenon lamp by the laser power supply, the xenon lamp generates light waves of a certain frequency and pulse width. The light waves then pass through the condenser cavity to irradiate the laser crystal, thereby exciting the crystal to produce laser. After passing through the resonant cavity, a pulsed laser with a wavelength of 1064nm is generated. The laser is transmitted through optical fibers, focused, and then radiated onto the surface of the workpiece. Welding is achieved by partially melting the workpiece.

It is applicable to the welding of connection parts and connectors in the electronics industry, medical industry, automotive industry, bathroom industry, eyewear industry, hardware industry, automotive industry, welding of metal casings and structural components of mobile phones, MP3 players, etc., welding of motor casings and wires, optical fiber connector joints, etc. Products for household hardware, kitchenware, electronic components, sensors, watches, precision machinery, communications, handicrafts and other industries, as well as high-strength industries such as automotive hydraulic tongs.