Product

The field of lasers

-

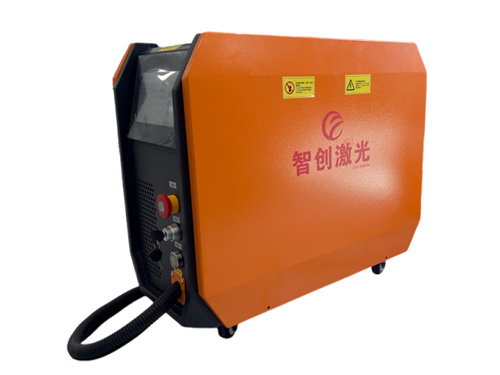

1500W air-cooled handheld welding

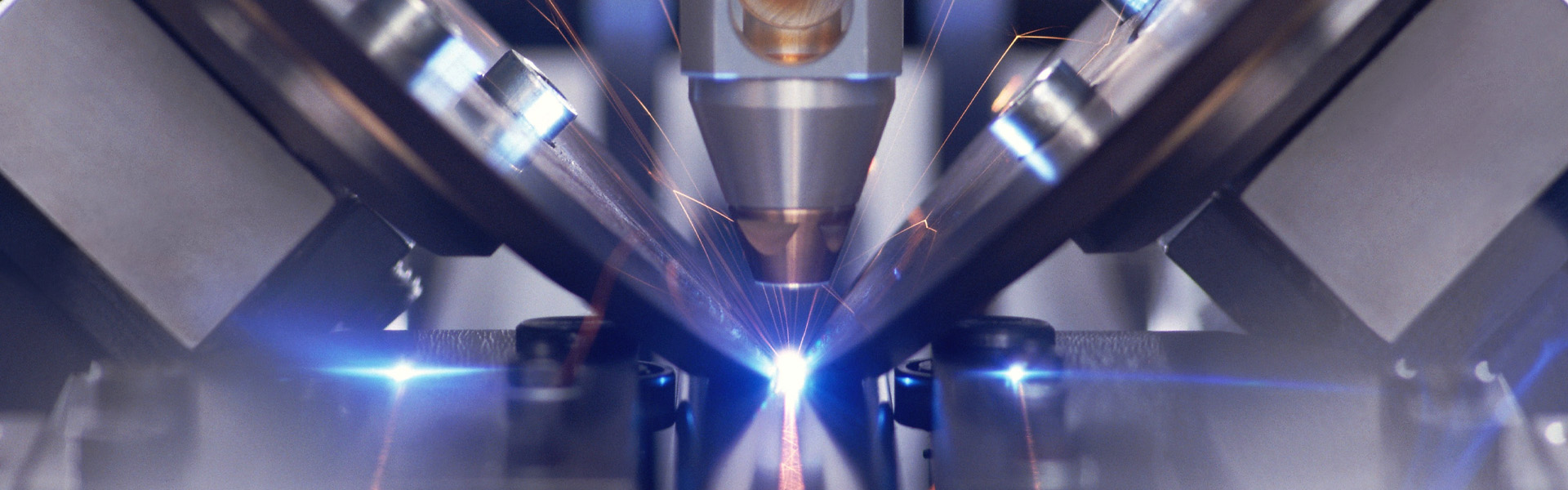

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+ -

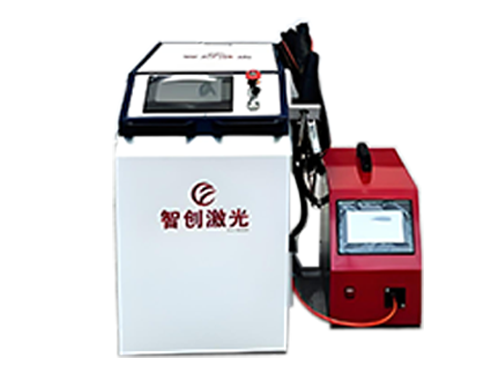

1500W water-cooled handheld welding

Water-cooled handheld welding generally refers to water-cooled handheld laser welding machines. Through the water-cooling system, the cold water in the chiller flows into the heat exchanger through water pipes to take away the heat generated by the operation of the laser, and then flows back to the chiller from the other outlet of the heat exchanger. This cycle continuously achieves heat dissipation, ensuring the stable operation of the laser.

More+ -

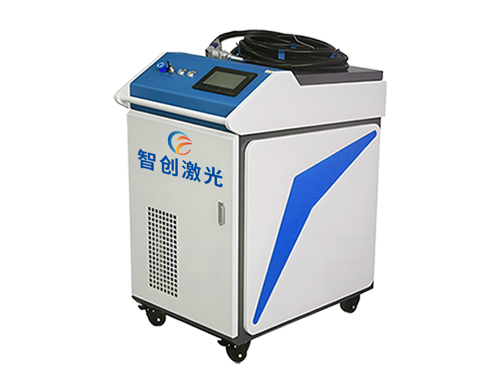

Water-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+ -

1200W air-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+