Product

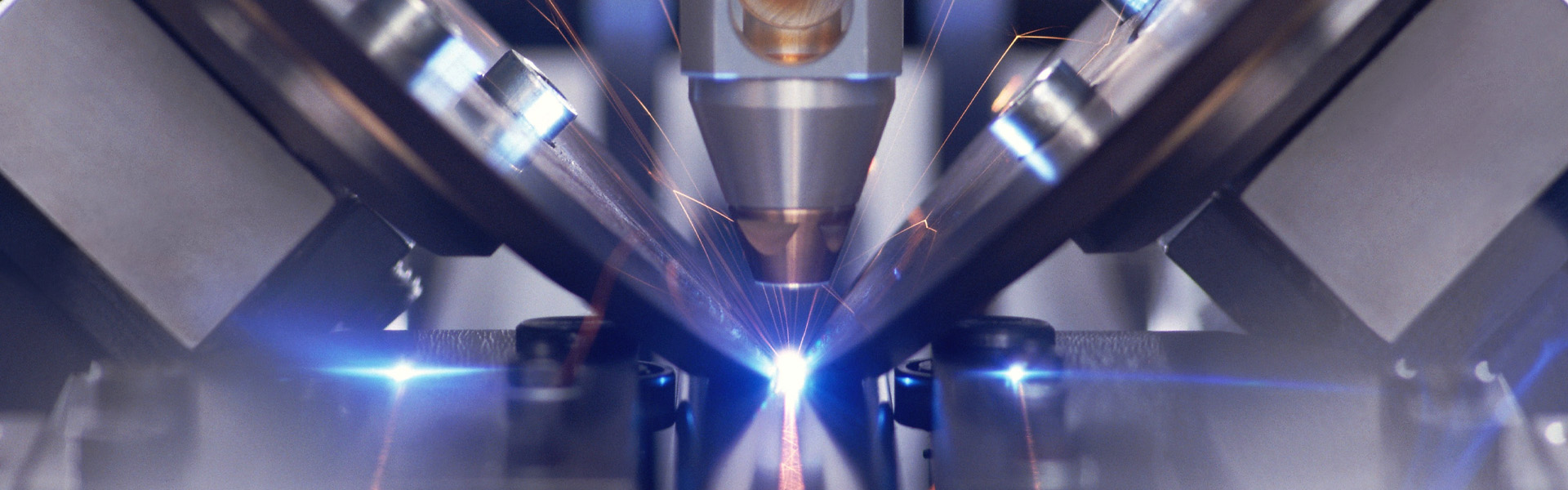

The field of lasers

-

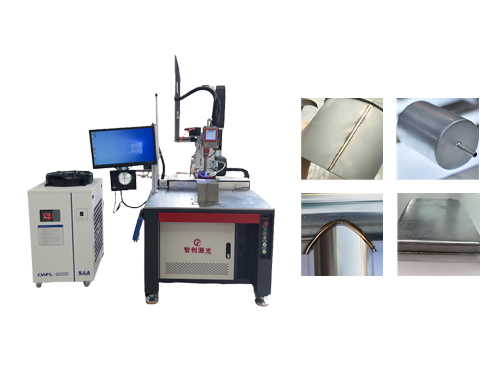

Fiber optic continuous laser automatic welding machine(Laser hardware welding)

Laser welding machine is currently a very popular laser equipment in the industrial field. Laser welding machine is not only a tool, but also a key force in promoting industrial innovation and development.

More+

It has brought new welding solutions to various industries with the characteristics of high precision, high efficiency, and high reliability, reshaping traditional welding processes -

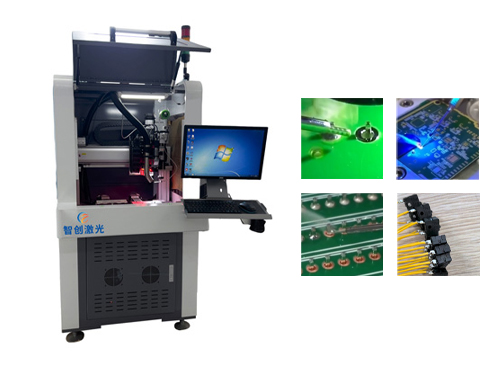

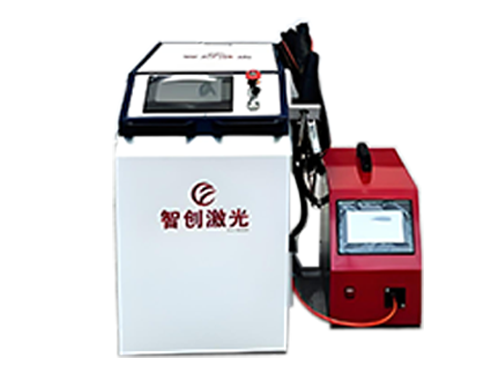

Laser soldering machine

The principle of laser soldering machine The laser soldering machine uses a laser beam as a welding heat source. By focusing a high-energy laser beam on the welding area, the solder is quickly melted and solidified.

More+

During the welding process, the laser soldering machine can achieve high-speed and high-precision welding, and has little thermal impact on the welding object.

This principle makes the laser soldering machine widely used in microelectronics manufacturing, electronic assembly and other fields. -

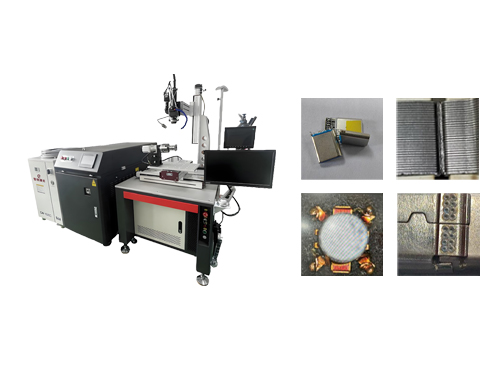

QCW welding motion platform(Laser hardware welding)

Quasi continuous (QCW) fiber lasers are an ideal choice for various industrial applications that require long pulse widths and high peak values, such as spot welding, seam welding, etc. This product is designed to replace some YAG laser welding applications, minimizing maintenance costs and reducing maintenance expenses. QCW can easily retrofit the vast majority of existing systems.

More+ -

4-axis single-station welding platform(Laser hardware welding)

A YAG laser is a type of laser that uses a xenon lamp as the laser source and a YAG laser crystal as the laser working substance. The laser power supply first pre-ignites the pulsed xenon lamp. Through the discharge of the pulsed xenon lamp by the laser power supply, the xenon lamp generates light waves of a certain frequency and pulse width. The light waves then pass through the condenser cavity to irradiate the laser crystal, thereby exciting the crystal to produce laser. After passing through the resonant cavity, a pulsed laser with a wavelength of 1064nm is generated. The laser is transmitted through optical fibers, focused, and then radiated onto the surface of the workpiece. Welding is achieved by partially melting the workpiece.

More+ -

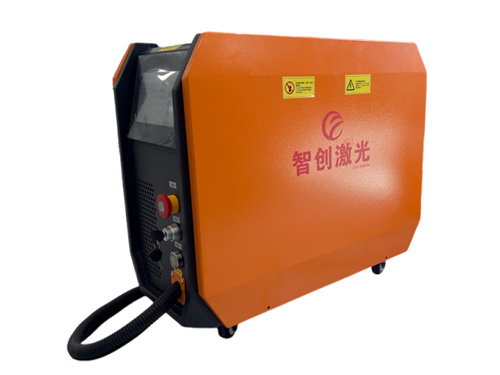

1500W air-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+ -

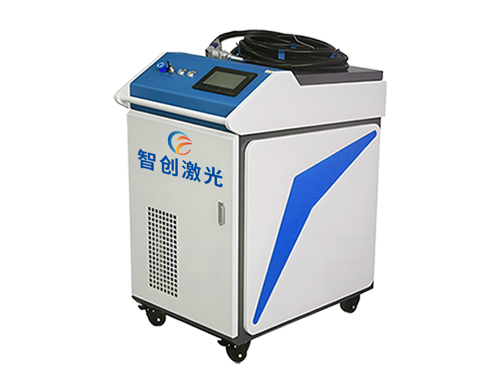

1500W water-cooled handheld welding

Water-cooled handheld welding generally refers to water-cooled handheld laser welding machines. Through the water-cooling system, the cold water in the chiller flows into the heat exchanger through water pipes to take away the heat generated by the operation of the laser, and then flows back to the chiller from the other outlet of the heat exchanger. This cycle continuously achieves heat dissipation, ensuring the stable operation of the laser.

More+ -

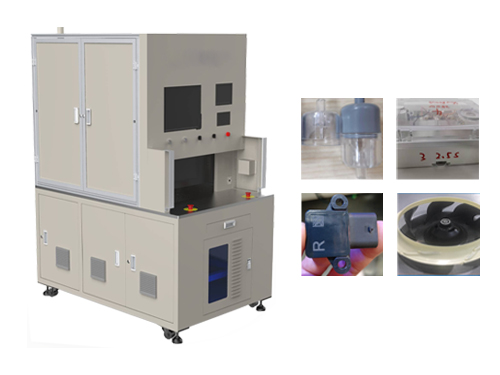

Plastic welding machine (plastic laser welding)

The welding method of using collimated and focused welding joints involves the focused laser spot moving along the welding path, sequentially melting and forming a weld seam. The workpiece can be fixed, and the laser welding head is mounted on a motion platform or robotic arm. The laser beam moves along the contour of the area to be welded; It is also possible to fix the laser beam and weld the workpiece along a predetermined trajectory.

More+ -

Water-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+ -

1200W air-cooled handheld welding

Laser welding uses a high-energy-density laser beam as a heat source to focus the laser beam within a very small range through an optical system, forming a highly concentrated energy heat source area at the weld in a very short time, thereby melting the welded material and forming a solid weld or weld. The smaller the focused spot, the greater the spot power density at the focal point, the higher the welding efficiency under the same welding penetration requirement, and the deeper the penetration after welding under the same welding efficiency requirement. Laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, melting the material to form a specific molten pool.

More+